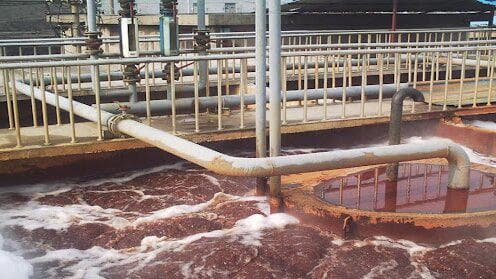

Application Examples in Industrial Wastewater Treatment: Removing Heavy Metal Ions

Background

In the treatment of industrial and mining wastewater, cobalt (Co²⁺), copper (Cu²⁺), and nickel (Ni²⁺) are common heavy metal pollutants. These metal ions are harmful to the environment and can pose health risks to humans. Therefore, an efficient method is needed to remove these metal ions from water.

Our company's MC910 Chelating ion exchange resins, with their high selectivity and adsorption capacity, are an ideal choice for removing these metal ions.

Operational Steps

Pre-treatment

- Filtration and Clarification: Pre-treat the wastewater through initial filtration and clarification to remove suspended particles and large impurities, preventing clogging of the resin bed.

- pH Adjustment: Adjust the pH of the wastewater to an optimal range (usually pH 4-6) based on the best adsorption conditions for the target metal ions.

Select Appropriate Chelating Resin

- Resin Type: Choose a chelating ion exchange resin with high selectivity for cobalt, copper, and nickel ions, such as iminodiacetic acid (IDA) type resin or ethylenediaminetetraacetic acid (EDTA) type resin.

Specific Effect

Through the above process, the concentration of cobalt, copper, and nickel ions in wastewater can be significantly reduced. The following is a comparison of the metal ion concentrations before and after treatment:

Before Treatment:

- Cobalt (Co²⁺): 100-200 ppm

- Copper (Cu²⁺): 150-250 ppm

- Nickel (Ni²⁺): 200-300 ppm

After Treatment:

- Cobalt (Co²⁺): < 1 ppm

- Copper (Cu²⁺): < 1 ppm

- Nickel (Ni²⁺): < 1 ppm

Conclusion

Using chelating ion exchange resin to treat wastewater containing cobalt, copper, and nickel effectively removes these heavy metal ions, ensuring the treated water meets environmental discharge standards or reuse standards. This method is not only environmentally friendly and efficient but also reduces treatment costs by regenerating the resin and recovering metals, achieving resource recycling.